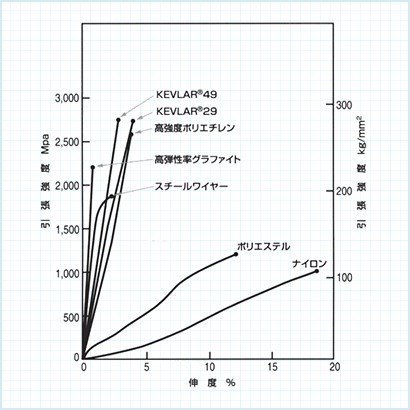

The graph shows the tensile properties per unit cross-sectional area of different materials.

Super Cord

KEVLAR®

KEVLAR® is the world's first super fabric developed in the 1960s.

Since then, it has maintained its cutting-edge position thanks to its remarkable properties as a material as well as technological innovations allowing to leverage such properties.

KEVLAR® can be processed to meet a variety of needs and has many application possibilities.

Physical properties characterizing KEVLAR® fiber

Table2-1. Physical properties characterizing KEVLAR®29 and KEVLAR®49

| Properties | Unit | KEVLAR®29 | KEVLAR®49 | ||

|---|---|---|---|---|---|

| YARN | Type | dtex | 1,670 | 1,270 | |

| (denier) | (1,500) | (1,140) | |||

| Number of filaments | 1,000 | 768 | |||

| Thread diameter: 12µm | |||||

| Density | g/cm3 | 1.44 | 1.44 | ||

| Moisture content | % | 7.0 | 3.5 | ||

| Equilibrium moisture content | % | 4.5 | 3.5 | ||

| Absolute dry mass: 24℃, 55%RH | |||||

| Fiber properties |

Tensile strength | cN /dtex | 20.3 | 20.8 | |

| (g/d) | 23.0 | 23.6 | |||

| Tensile elasticity | cN /dtex | 490 | 780 | ||

| (g/d) | 555 | 855 | |||

| Fracture elongation | % | 3.6 | 2.4 | ||

| Epoxy resin impregnated strands |

Tensile strength | Mpa | 3,600 | 3,600 | |

| Tensile elasticity | Mpa | 83,000 | 124,000 | ||

| Thermal properties |

Thermal contraction |

100℃ hot water | % | く0.1 | く0.1 |

| 177℃ dry heat | % | く0.1 | く0.1 | ||

| Thermal contraction response |

177℃ dry heat | cN/tex | く0.88 | く1.77 | |

| g/d | く0.1 | く0.2 | |||

| Specific heat | 25℃ | J/ (kg×K) | 1,420 | 1,420 | |

| 100℃ | J/ (kg×K) | 2,010 | 2,010 | ||

| 180℃ | J/ (kg×K) | 2,515 | 2,515 | ||

| Combustion heat (decomposition temperature in air) |

℃ | 427〜482 | 427〜482 | ||

- DuPont™ and KEVLAR® are registered trademarks of DuPont.

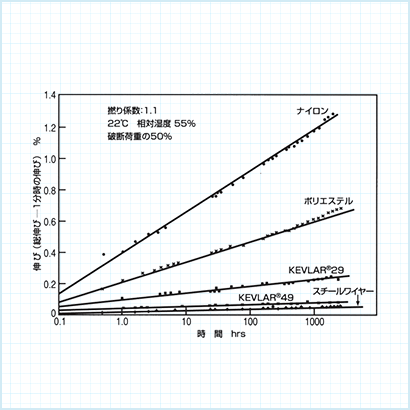

Tensile properties of KEVLAR®

Tensile properties per unit cross-sectional area of different materials

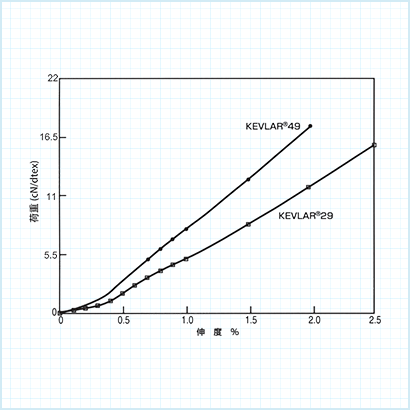

Stress-strain curve of unprocessed fiber under low strain

The graph shows the stress-strain curves of KEVLAR®29 and 49 under low strain.

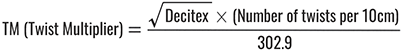

Tensile strength when spun

When fibers are spun, they exhibit different physical properties. The graph shows the changes in strength, elasticity and elongation. KEVLAR® exhibits the highest tensile strength when the twist multiplier is 1.1, at which the physical properties of unprocessed threads are usually observed. The twist multiplier is calculated using the following formula, which allows threads of different sizes to have the same twist angle.

Stress-strain curve of unprocessed fiber under low strain

The graph shows a very favorable creep modulus of KEVLAR®.

- DuPont™ and KEVLAR® are registered trademarks of DuPont.