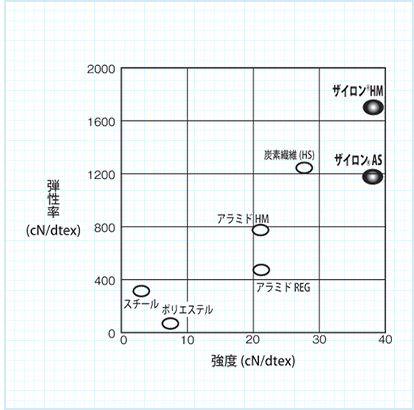

ZYLON® is twice stronger and more elastic than para-aramid fibers, having the highest strength and elasticity among organic fibers.

Super Cord

ZYLON®

ZYLON® is a fiber spun from liquid-crystalline poly-phenylene benzobisoxazole (PBO) which has a rigid and very linear molecular structure.

It is the next generation super fiber enabled by the latest material science and fiber technology.

Comparison of physical properties

| Strength | Elasticity | Elongation | Density | Moisture content | LOI | Heat resistance* | |||

|---|---|---|---|---|---|---|---|---|---|

| g/d | GPa | g/d | GPa | % | g/cm3 | % | - | ℃ | |

| ZYLON®AS | 37 | 5.8 | 1150 | 180 | 3.5 | 1.54 | 2.0 | 68 | 650 |

| ZYLON®HM | 37 | 5.8 | 1720 | 270 | 2.5 | 1.56 | 0.6 | 68 | 650 |

| Para Aramid HM | 19 | 2.8 | 750 | 109 | 2.4 | 1.45 | 4.5 | 29 | 550 |

| Meta Aramid | 4.7 | 0.65 | 124 | 17 | 22 | 1.38 | 4.5 | 29 | 400 |

| Steel fiber | 3.5 | 2.8 | 260 | 200 | 1.4 | 7.8 | 0 | - | - |

| Carbon fiber | 20 | 3.5 | 1310 | 230 | 1.5 | 1.76 | - | - | - |

| IZANAS®AS | 35 | 3.5 | 1230 | 123 | 3.5 | 0.97 | 0 | 17 | 150 |

| PBI | 2.7 | 0.4 | 40 | 5.6 | 30 | 1.4 | 15 | 41 | 550 |

| Polyester | 8 | 1.1 | 110 | 15 | 25 | 1.38 | 0.4 | 17 | 260 |

- Decomposition or melting temperature

Characteristics of ZYLON®

High strength and elasticity

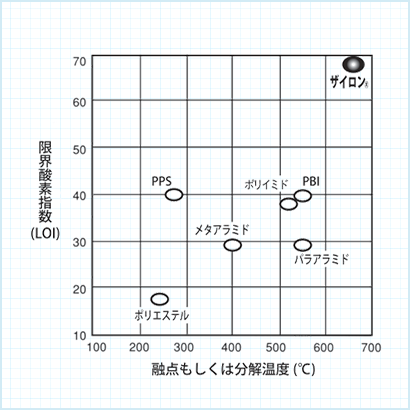

Heat and frame resistance

ZYLON®'s decomposition temperature is 100℃ higher than that of para-aramid fibers.

Its limiting oxygen index (LOI) of 68 is also the highest among organic fibers, meaning that it requires the highest concentration level of oxygen to maintain combustion.

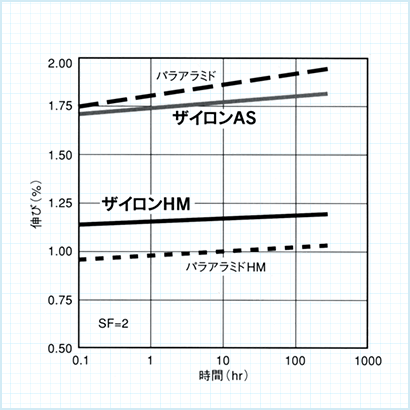

Creep resistance

"ZYLON® offers outstanding creep resistance.

When ZYLON® HM is applied with a load equal to half its rupture strength for 100 hours, it exhibits permanent elongation less than 0.03%.

- ZYLON® is a registered trademark of Toyobo.